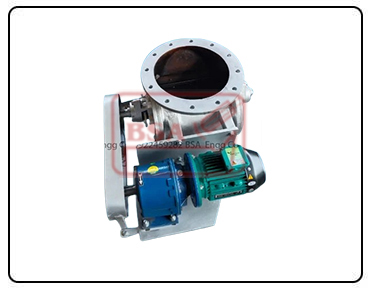

Round Rotary Airlock Valve Manufacturers in USA

BSA Engineering Company are one of the most reliable Round Rotary Airlock Valve manufacturers, suppliers, and exporters of USA, and we manufacture superior quality valves with the potential to transfer dry bulk solids in pneumatic and gravity systems. Our round rotary airlock valves are built with the seal performance, flow precision, and long time reliability—most especially those applications that entail free flowing unbroken material flow.

Round valve forms of ours are used in cylindrical or round interface applications and offer alignment ease and convenience and ease of integration into different hoppers, silos, bag filters, and conveyor systems.

Types of Round Rotary Airlock Valve

As one of the leading Round Rotary Airlock Valve manufacturers in USA, we are offering premium quality Round Rotary Airlock Valve including:

- Standard Round Rotary Airlock Valve

General purpose airlock valve for general application to dust collection systems and pneumatic conveying systems include round shape flange, accurately machined rotors, close sealing with free flow feature with less leakage. - Drop Through Round Rotary Valve

The best suited for gravity-discharged discharge from hoppers and silos, the model provides unhampered free vertical flow of bulk material by the valve. Jamming is prevented by low-speed discharge and minimal rotor-to-housing clearance. - Blow Through Round Rotary Airlock Valve

Used in pressurized pneumatic conveyor systems, the model features streamlined internal design, press-fit airlocks, and adjustable-speed drives to provide maximum material transportation in horizontal transport systems. - Heavy-Duty Round Rotary Valve

Designed to perform applications with the utilization of high-abrasion materials such as cement, sand, or minerals. Long-lasting durable bearings, heavy-duty rotor blades, and long-lasting wear-resistant coating are utilized to provide steadfast operation under harsh conditions. - Custom Round Rotary Airlock Valve

Specific specifications of plants are carried out to create personalized valves which could be manufactured using ATEX-rated equipment, heat-resisting material, food-grade paint, and automatic sensors depending upon the requirement.

Our New Features of Round Rotary Airlock Valve

As one of the premier Round Rotary Airlock Valve manufacturers in USA, our all-kinds of Round Rotary Airlock Valve are designed with new technology formula such as:

- CNC-Machined Round Housings and Flanges: Machine-built valves for improved accuracy to achieve accurate roundness and positioning for air-tight coupling with minimal vibration.

- Air Purge Shaft Seal Technology: By pressurized seals protecting against dust entry into the bearing housing, hence prolonging the life of the valve and minimizing maintenance cycles.

- Smart Monitoring Integration: Units with IoT sensors integrated to track rotor speed, working temperature, and system pressure in real-time to allow predictive maintenance.

- VFD-Ready Drives: Valves are VFD-compatible and offer accurate speed control of the rotor for dynamic adjustment in automated processes.

- Material-Specific Enhancements: Stainless steel manufacturing, nickel or Teflon plating, and rotor design to optimize material flow properties and environmental stresses.

Benefit of our use of Round Rotary Airlock Valve

All aforementioned said new Round Rotary Airlock Valve in USA, provide different kinds of benefits such as:

- Consistency of Flow Control: Symmetrical flow pattern design offers beneficial round configuration, reducing material buildup and discharge accuracy when placed vertically and horizontally.

- Space-Saving, Compact Installation: Low-space installations are suited to these valves, which nest tightly in round duct, filter units, or silos without or with slight alteration.

- Fault-Free Air Sealing: Improved demanding rotor clearance and state-of-the-art sealing technology provide pressure differences to ensure air leakage is prevented and energy is saved.

- Extended Equipment Life: With long-lasting internals, air purge seal and high-performance coating technology, these valves provide longer performance cycles and reduced wear and tear in life.

- Automation and Smart Operation: Designed to be installed on SCADA, PLC, and Industry 4.0 technology to make the plant as efficient as possible and also provides real-time monitoring and control.

Applications of Our Round Rotary Airlock Valve

As a leading Round Rotary Airlock Valve exporters in USA, all service categories are New feature incorporated and have broad application in broad applications like:

- Pneumatic Conveying Lines: Utilized at feed or discharge locations where constancy in pressure and material feeding should be provided to provide system reliability.

- Cement & Minerals Industry: Heavy-duty application with capacity to handle with dry cement, gypsum, fly ash, or sand where round flanges are typically necessitated.

- Chemical & Plastics Processing: Handle fine powders, granules, and reagent chemicals under high-purity processing with corrosion-resistant round rotary valves.

- Fertilizer & Agriculture Industry: Discharges DAP powders and granules or urea from low-clog cylindrical silos with uniform flow.

- Food & Pharma Industry: Employed to transport flour, spices, milk powder, or APIs, especially where sanitary design stainless steel models are installed.

- Dust Collection Systems: Installed over cyclone, separator, and bag filter round flanges, the valves control efficient discharge of dust and system vacuum integrity.

We are leading Round Rotary Airlock Valve manufacturers, suppliers and exporters in USA. It is our responsibility at BSA Engineering Company to offer accurate, accuracy-made parts to touch your production line. Being a quality supplier, and exporter of Round Rotary Airlock Valve in USA, we export innovation, quality, and smart thinking in each valve we export. Whether off-the-shelf or custom-built, our round rotary valves are engineered to optimize flow efficiency, optimize years of service, and enable automatic plant operation with least effort. Select BSA for reliable solutions that work and are made to last.

-

Our LocationPuneIndiaUAEUSA