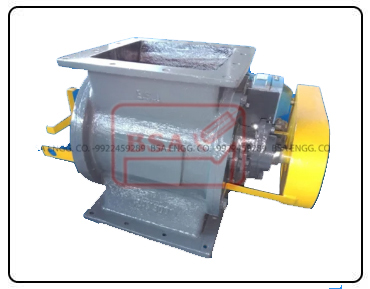

Rotary Valve Manufacturers in India | Rotary Valve Suppliers in India

We BSA Engineering Company are proud to be the leading rotary air lock valve manufacturers and suppliers in India.

These essential components serve a pivotal role across diverse industrial sectors by facilitating efficient material transfer and effectively reducing air and gas pressure. Crafted with meticulous attention to quality, our rotary valves ensure optimal performance and reliability in every application. As leaders in the field, we are dedicated to delivering superior products that meet the specific demands of our clients, reinforcing our position as the foremost provider of rotary valve manufacturers in India.

As a reputed rotary valve suppliers in India, our product range at BSA Engineering Company encompasses a diverse array of rotary valves, including drop-through rotary valves, industrial air lock valves, air lock valves, rotary air lock valves, industrial rotary valves, and numerous other essential items. Each of these valves is meticulously designed to meet the stringent demands of various industrial applications, ensuring efficient material handling and reliable operation. We pride ourselves on being among the foremost rotary valves in India, offering a comprehensive selection that caters to the specific needs of our clients. This reflects our unwavering commitment to excellence in rotary valve technology.

What is a Rotary Valve?

A rotary valve, also known as a rotary feeder, is a mechanical device used to regulate the flow of bulk materials from one chamber to another, maintaining a consistent flow rate and preventing air leakage. It consists of a rotor with multiple vanes that rotate within a housing, allowing materials to drop through the feeder while controlling the flow rate. Rotary valves are commonly used in industries such as food processing, pharmaceuticals, and chemical manufacturing. In India, numerous manufacturers specialize in rotary valves, offering a range of products designed to meet the specific needs of different industries. These manufacturers focus on delivering high-quality, durable, and efficient rotary valves to ensure optimal performance in material handling applications.

Technical Specifications of Rotary Valve in India

As reputable rotary valve suppliers in India, we have multiple specification as discuss below:

| Parameter | Value |

| Design Type | Round & Square |

| RAV Size | 150 mm to 600 mm |

| Material (MOC) | Cast Iron / SS 304 / MS |

| Rotor (MOC) | MS Fabricated (Vanes = 08 Nos.) |

| Drive (Gear - Motor) | 0.5 HP to 5 HP |

| Application | Fly Ash, Cement, Clinker, Sponge, Iron, Coal, Dust, etc |

Types of Rotary Valve in India

At leading rotary valve manufacturers in India, we offer a comprehensive range of rotary valves designed to meet diverse industrial needs. Below are detailed descriptions of our key products:

- Drop-through Rotary Valve: As trusted rotary valve suppliers in India, our drop-through rotary valves are engineered for handling bulk materials with a continuous flow requirement, ensuring seamless processing in various industrial applications. These valves maintain material integrity while facilitating efficient material transfer in systems requiring consistent performance.

- Blow-through Rotary Valve: Designed specifically for powders and granular materials, our blow-through rotary valves ensure precise pneumatic conveying by maintaining a controlled airlock. Ideal for industries requiring clean and efficient material handling, such as food processing and chemical industries, these valves enhance operational reliability and minimize material leakage.

- Side-entry Rotary Valve: As prominent rotary valve manufacturers in India, our side-entry rotary valves are suitable for installations where space is limited. These valves offer ease of maintenance and reliable performance, making them ideal for applications in industries such as pharmaceuticals, where hygiene and operational efficiency are critical.

- Sanitary Rotary Valve: Engineered to meet stringent sanitary standards, our sanitary rotary valves are essential for industries demanding hygienic handling of materials, such as food and beverage processing. These valves feature smooth surfaces and easy disassembly for thorough cleaning, ensuring contamination-free operations and compliance with industry regulations.

- Heavy-duty Rotary Valve: Built to withstand abrasive materials and harsh environments, our heavy-duty rotary valves are designed for durability and reliability in demanding industrial settings like mining and cement production. These valves provide robust performance, ensuring efficient material flow and extended service life under challenging conditions.

Applications of Rotary Valve:

Our company offers high-quality rotary valve manufacturers in India, designed to meet the diverse needs of various industries:

- Food Processing Industry: Ensure consistent feeding of powders and granules such as flour, sugar, spices, and grains, while maintaining hygiene standards and preventing contamination. Our rotary valves are perfect for feeding processing equipment and packaging lines.

- Pharmaceutical Industry: Provide precise metering and control of powdered and granular materials, crucial for maintaining production integrity and preventing cross-contamination. Our valves ensure accurate dosage and compliance with stringent industry standards.

- Chemical Industry: As leading rotary valve suppliers in India, our rotary valves maintain a controlled, dust-free environment, essential for the processing and management of chemical powders, granules, and pellets.

- Cement and Construction Industry: Efficiently manage raw materials like limestone, clinker, and gypsum. Our valves also handle fly ash and other additives, ensuring a consistent and controlled material flow in concrete production.

- Plastics Industry: Enable consistent feeding of plastic resins, pellets, and powders to extrusion and molding machines, enhancing product quality and process efficiency.

- Agriculture Industry: Offer reliable solutions for handling and processing agricultural products such as grains, seeds, and animal feed. Our rotary valves provide controlled discharge from storage bins and silos, aiding efficient material handling and distribution.

- Power Generation Industry: Manage coal, biomass, and other fuel materials fed to boilers and furnaces. Our valves enhance the efficiency of power generation processes by maintaining a controlled and consistent feed rate.

Leading rotary valve manufacturers in India rely on us for these benefits, ensuring optimal performance and reliability in their material handling processes.

As a reputable rotary valve manufacturers and suppliers in India. We understand that every application has unique requirements. That's why BSA Engineering Company offers a wide range of options to meet all your needs. Contact us today to discuss how our rotary valves can optimize your material handling processes and elevate your industrial operations.

-

Our LocationPuneIndiaUAEUSA