Cast Iron Rotary Airlock Valve Manufacturers in USA

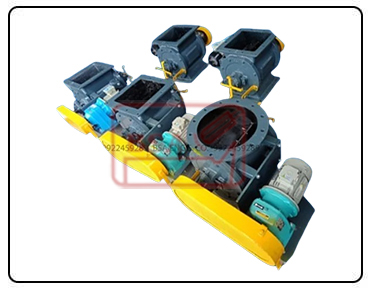

BSA Engineering Company is a leading Cast Iron Rotary Airlock Valve manufacturers, suppliers and exporters in USA. We offer precision-engineered solutions to work solely for bulk solid handling, dust control, and pneumatic conveying systems alone.

Our Cast Iron Rotary Airlock Valves are made with ultimate structural strength, seal intentionally designed courses, and recently designed improvements for efficiency, security, and extended working life. The valves protect pressure differential and regulate powder, granule, and abrasive material flow in most industrial processes.

Types of our Cast Iron Rotary Airlock Valve

Being one of the premier manufacturers of Cast Iron Rotary Airlock Valve in USA, we have been providing the superior quality standard of Cast Iron Rotary Airlock Valve like:

- Standard Cast Iron Rotary Airlock Valve

For total service from dry powder discharge to secondary applications as diverse, model valve is constructed of heavy-duty cast iron, close tolerance machined rotors, and reversible packing seals for smooth, leak-free operation. - Drop Through Cast Iron Rotary Valve

Used in silos and hoppers for gravity feed use, the valves have drop-through design with disposition in vertically mounted position to ensure free flow discharging of material without any obstruction. Zero air loss and friction-free flow are achieved with dust-tight additive shaft seal and smooth-machined inlet ports. - Blow Through Cast Iron Rotary Airlock Valve

Specifically designed for installation in pneumatic conveying pipe line, the valve provides direct pressure system discharge. New releases incorporate air purge technology, over-strength rotors, and vibration-resistance seals to provide control at high flow pressures. - Heavy-Duty Cast Iron Rotary Valve

Fabricated in size with and on skid base to provide maximum access, the valve features thick walled castings, hardened steel cutters, and surface bearing assemblies for operation under harsh operating stress. - Special Cast Iron Rotary Airlock Valve

We fabricate them to special industries and do have IoT sensor ports, anti-corrosion protection, VFD-compatible drives, and special rotor designs to accommodate special plant requirements.

Features of our Cast Iron Rotary Airlock Valve

As leading Cast Iron Rotary Airlock Valve suppliers in USA, our all-types of Cast Iron Rotary Airlock Valve are backed by latest technology formulations including:

- Advanced Shaft Sealing Systems: With air purge or mechanical seals for lower leakage and contamination for longer service life in application examples with dust.

- Intelligent Rotor Design and CNC Machining: Rotors are precisely machined to near tolerance in CNC machines to achieve maximum airlock sealing, optimum wear life, and minimum clearance.

- Sensor and Automation Integration: Optional IoT feature for real-time monitoring of rotor speed, vibration, temperature, and valve position to facilitate predictive maintenance and remote diagnosis.

- VFD Compatibility: Valves may be supplied to be fitted into variable speed drive control so throughput can be controlled directly in addition to being capable of controlling the material rate of feed as process conditions vary.

- Material-Specific Adjustments: From Teflon-lined liners to nickel-plated finishes, we also stock a range that are constructed with the durability and flexibility of high-moisture, heat-high, or corrosive applications.

Benefits of our Cast Iron Rotary Airlock Valve

All the aforementioned new Cast Iron Rotary Airlock Valve in USA, offer different types of benefits such as:

- Structural Strength and Shelf Life: Greater mechanical strength is offered by cast iron, which allows the valve to work under constant load without deformation or failure due to wear-out or fatigue.

- Pressure Isolation Success: With highly engineered rotor-to-housing clearances and industry-best seals, our valves offer unparalleled airlock performance in vacuum service and pressurized service.

- Low Maintenance and Operating Expense: Our heavy-duty construction and leading-class sealing technology reduce breakage, lubrication, and replacement of spare parts—enabling lower long-term maintenance expense.

- Automation and Integration System: With sensor, actuator, and PLC interface capability, our valves are leaders in Industry 4.0 integration and simple to integrate into advanced automated material handling systems.

Applications of our Cast Iron Rotary Airlock Valve

As USA Cast Iron Rotary Airlock Valve exporters, our each service is supported with a new feature and is being used to good extent in various applications like:

- Cement & Building Material Industry: Our cast iron fly ash and cement, gypsum, and abrasive materials valves flow with reliable airlock action and reduced wear.

- Dust Collection and Filtration Systems: Usually mounted underneath cyclones, bag filters, and scrubbers to enable dust release with no reduction in air pressure and system stability.

- Food and Feed Production Plants: Pre-treatment or non-hygienic areas where controlled release of grain or feed pellets by virtue of proper design is critical.

- Chemical & Fertilizer Plants: Optimum for relief of dry powders, resins, and pressurized granular fertilizers with optional corrosion-resistant options for aggressive materials.

- Power Plants & Biomass Boilers: Located on ash handling transmission and solid fuel feeding ducts where coarse particles and heat require a tough Airlock solution.

- Mining & Mineral Processing Plants: Reliefs abrasive and abrasive bulk materials such as ores, limestone, or sand—allowing neat flow control in heavy wear applications.

BSA Engineering Company is a prominent Cast Iron Rotary Airlock Valve manufacturers, suppliers and exporters in USA. We specialize in delivering industrial solutions with the perfect combination of strength, efficiency, and innovation. As a quality Cast Iron Rotary Airlock Valve manufacturer, supplier, and exporter in USA, we integrate proven-tested material with the finest designs to deliver valves that perform better day by day in the challenging processing environments of today. Every time you upgrade your equipment or install new flow control devices, our cast iron rotary valves are built to last—and strong enough for whatever lies ahead in industrial automation

-

Our LocationPuneIndiaUAEUSA